Overview of Chicken Feed Pellet Machines

A chicken feed pellet mill refers to specialized mechanical equipment used to convert mixed poultry feed ingredients into compact pellets suitable for chicken consumption. These machines are a core component of modern poultry feed manufacturing, serving farms, feed mills, and integrated poultry production systems.

By transforming loose feed materials into uniform pellets, chicken feed pellet machines improve feed handling efficiency, reduce waste, and ensure consistent nutrient intake across poultry flocks. Their widespread use reflects the increasing mechanization and standardization of poultry nutrition worldwide.

Historical Development of Chicken Feed Pelleting

Historically, chickens were fed whole grains or simple mash diets prepared on farms. While this approach was sufficient for small-scale poultry keeping, it often resulted in selective feeding and uneven nutrient intake.

The introduction of feed pelleting technology in the early 20th century marked a major advancement in animal nutrition. Initially developed for livestock, pelletizing equipment was later adapted for poultry feed production. As poultry farming became more industrialized, dedicated chicken feed pellet machines were developed to meet the specific dietary and physical feed requirements of chickens at different growth stages.

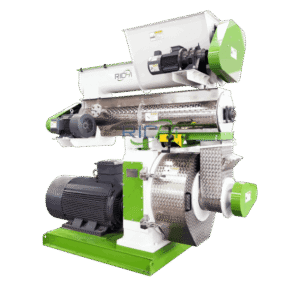

Basic Structure of a Chicken Feed Pellet Machine

A chicken feed pellet machine consists of several essential components that work together to produce uniform feed pellets.

Feeding System

The feeding system regulates the flow of raw materials into the pelletizing chamber. A stable and controlled feed rate is essential for maintaining consistent pellet quality and machine performance.

Pelletizing Unit

The pelletizing unit is the core working section of the machine. Inside this unit, feed materials are compressed through a die by rotating rollers. Heat generated by friction and pressure allows the feed particles to bind together and form pellets.

Drive and Transmission System

This system includes the motor, gearbox, and transmission components. It supplies the mechanical power required for continuous operation and directly affects production capacity and energy efficiency.

Types of Chicken Feed Pellet Machines

Chicken feed pellet machines for sale are available in different configurations, depending on production scale and operational requirements.

Flat Die Pellet Machines

Flat die pellet machines are commonly used in small and medium-sized poultry farms. They feature a simple structure, compact size, and relatively low investment cost, making them suitable for on-site feed production. https://richipelletizer.com/chicken-feed-pellet-making-machine/

Ring Die Pellet Machines

Ring die pellet machines are widely used in commercial feed mills and large poultry operations. They offer higher output, better pellet consistency, and longer service life. Equipment manufacturers such as RICHI provide ring die pellet machines designed for continuous and large-scale poultry feed production.

Raw Materials Used in Chicken Feed Pelleting

Chicken feed pellet machines are designed to process a wide variety of feed ingredients, allowing flexibility in feed formulation.

Common raw materials include:

Corn, wheat, and sorghum as primary energy sources

Soybean meal and rapeseed meal as protein sources

Wheat bran and other agricultural by-products

Vegetable oils or animal fats for energy density

Vitamin and mineral premixes

Proper grinding and mixing of these materials are essential to ensure pellet quality and nutritional balance.

Pellet Size and Feed Form for Chickens

Chicken feed pellets are produced in different sizes and forms to match the feeding needs of birds at various life stages.

Starter Feed Pellets

Small-diameter pellets or crumbles are used for chicks, providing easy intake and high nutrient availability during early growth.

Grower Feed Pellets

Medium-sized pellets support steady growth and efficient feed conversion during the intermediate stage.

Layer and Finisher Feed Pellets

Larger pellets are designed for adult chickens, focusing on egg production, shell quality, or final weight gain.

Chicken feed pellet machines can be adjusted to produce pellets with different diameters and lengths to meet these requirements.

Nutritional and Operational Advantages

The use of a chicken feed pellet machine offers several advantages over traditional mash feeding.

Improved Feed Efficiency

Pellets prevent selective feeding, ensuring that chickens consume a balanced diet with each bite.

Enhanced Digestibility

The heat and pressure applied during pelleting improve starch gelatinization and nutrient availability.

Reduced Feed Waste

Pelleted feed is less likely to be spilled or blown away, particularly in automated feeding systems.

Applications in Poultry Production Systems

Chicken feed pellet machines are used across a wide range of poultry production environments.

Broiler Farming

Broiler operations rely on pelleted feed to achieve rapid growth rates and efficient feed conversion.

Layer Farming

Layer hens benefit from nutritionally consistent pellets that support egg production, shell strength, and overall health.

Breeder Operations

Breeder flocks require carefully formulated feed to maintain reproductive performance and chick quality.

Global Market and Trade Perspective

The global poultry industry continues to expand, driving demand for efficient feed processing equipment. A chicken feed pellet machine for sale is commonly traded internationally, particularly in regions experiencing rapid growth in poultry production, such as Asia, Africa, and South America.

International suppliers, including RICHI Pelletizer, participate in this market by providing machines that meet diverse production capacities, raw material conditions, and regulatory standards. Global trade in poultry feed equipment supports local feed manufacturing and reduces dependence on imported feed products.

Installation and Operational Considerations

Proper installation and operation are essential for maximizing the performance of a chicken feed pellet machine.

Key considerations include:

Stable machine foundation and alignment

Adequate power supply and electrical protection

Consistent raw material preparation

Operator training and safety procedures

Attention to these factors helps ensure stable operation and consistent pellet quality.

Maintenance and Service Life

Routine maintenance is critical for extending the operational life of a chicken feed pellet machine.

Typical maintenance activities include:

Regular inspection of dies and rollers

Lubrication of bearings and transmission components

Monitoring of motor load and operating temperature

Replacement of worn parts at appropriate intervals

With proper maintenance, chicken feed pellet machines can operate reliably for many years. Visit this web-site

Environmental and Sustainability Considerations

Modern chicken feed pellet machines are increasingly designed with sustainability in mind. Improved energy efficiency, reduced dust emissions, and optimized material flow contribute to environmentally responsible feed production.

The ability to utilize locally sourced grains and agricultural by-products further supports sustainable poultry farming practices.

Conclusion

A chicken feed pellet machine for sale is an essential piece of equipment in modern poultry feed manufacturing. By converting diverse raw materials into uniform, nutritionally balanced pellets, these machines support efficient feed utilization, improved poultry performance, and scalable production. As global poultry demand continues to rise, chicken feed pellet machines will remain a key technology in the poultry feed industry. Chicken Feed Plant in Iran